ADDEV Material Healthcare Celebrates 70 Years of Business Excellence

70 Years ago, the world was a very different place. The US was in the midst of the cold war, people drove around Chevrolet Bel Airs and Elvis had just released his first single. Amongst all that exciting history, ADDEV Material Healthcare was born.

AMH's Origin

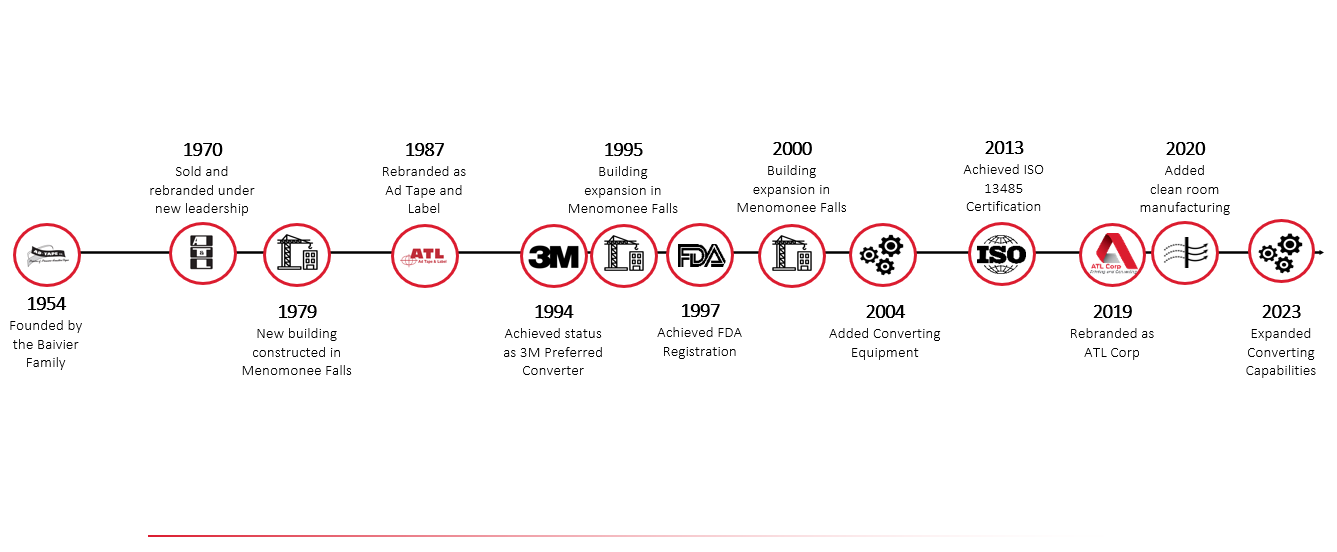

Ad Tape was founded in 1954 by the Baivier family in Milwaukee, Wisconsin. Ad Tape started as a printing company, specializing in advertising tape used for packaging. The Baivier's were committed to quality and helping customers bring their products to life.

The business was sold in 1970 and the company's name was updated to Ad Tape and Label to recognize the growing label business. With a continued commitment to helping customers succeed, it became apparent a new location was needed. Ad Tape and Label outgrew the production facility in Milwaukee and in 1979, found a new location just northwest of Milwaukee, in Menomonee Falls, WI. This new location and its added capacity fueled the growth of Ad Tape and Label as it introduced new technologies and expanded capabilities.

Ad Tape and Label was sold in 1987. With a vision of growth and strengthening capabilities, many developments followed, including two building expansions.

From the beginning Ad Tape and Label recognized the importance of building strategic relationships with the leading raw material suppliers. In 1994 ADDEV Material Healthcare earned the prestigious distinction of being a 3M Preferred Converter (now known as Solventum). This important connection assisted Ad Tape and Label in providing customers with technical material expertise and project selection.

strategic relationships with the leading raw material suppliers. In 1994 ADDEV Material Healthcare earned the prestigious distinction of being a 3M Preferred Converter (now known as Solventum). This important connection assisted Ad Tape and Label in providing customers with technical material expertise and project selection.

ADDEV Material Healthcare earned FDA registration in 1997, recognizing the opportunity to further expand its offering to the health care market.

Continued Growth for ADDEV Material Healthcare

In 2004, ADDEV Material Healthcare invested in its first precision rotary die cutting converting equipment with new advanced servo technology, close-loop registration, and in-line vision inspection. This investment allowed ADDEV Material Healthcare to expand its capabilities into a more technologically advanced producer for the medical device industry.

Over the last few years, ADDEV Material Healthcare has installed many printing and converting machines for flexographic printing, digital printing, and material converting. Providing expertise in both printing and converting gives ADDEV Material Healthcare a competitive advantage in serving global healthcare customers.

Ad Tape and Label earned ISO 13485:2016 certification in 2013. ISO 13485 is a Quality Management System Certification established by the International Organization for Standardization for the manufacture of medical devices. This certification enforces regulatory requirements that the organization must meet. ADDEV Material Healthcare strongly believes that a strong quality system leads to consistently high-quality products. Our quality systems are paramount to both our customers' satisfaction and our continued growth as a company.

In 2019, Ad Tape and Label rebranded as ADDEV Material Healthcare, welcoming a new chapter of continued growth and manufacturing excellence dedicated to customer success.

a new chapter of continued growth and manufacturing excellence dedicated to customer success.

By 2020, ADDEV Material Healthcare expanded its facility to include ISO-certified class 7 and class 8 clean rooms. The installation of these clean rooms was part of an aggressive, strategic plan to support growth and healthcare market expansion. Clean rooms are designed to maintain extremely low levels of particulates, such as dust, chemical vapors, aerosol particles, or airborne organisms.

Celebrating 70 Years

AMH's roots in printing grew over the years to include material converting and cleanroom manufacturing. From the start, ADDEV Material Healthcare has been laser-focused on helping customers bring their products to life. ADDEV Material Healthcare is known for our creative thinking, problem-solving capabilities, and craftsmanship in producing high-quality products for our customers. For 70 years, ADDEV Material Healthcare has excelled at providing exceptional service to our customers, and we look forward to doing the same for the next 70 and beyond.