Multi-Layer Laminating

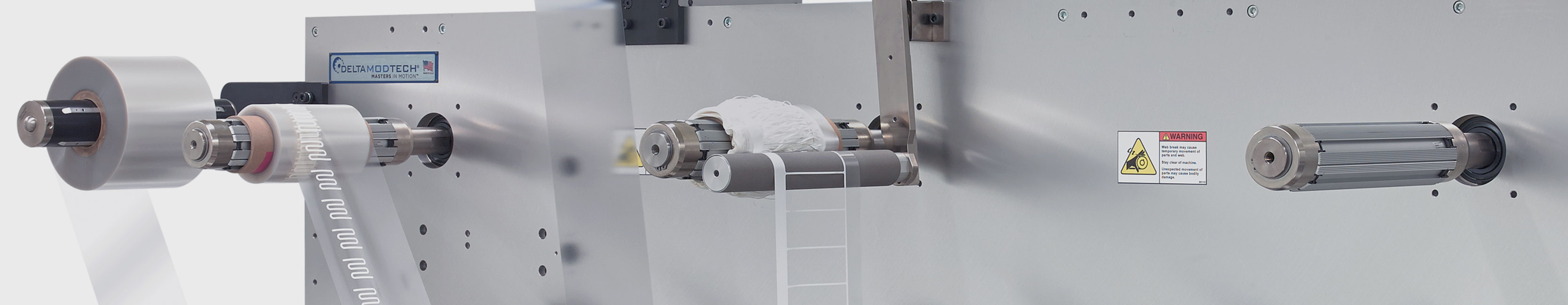

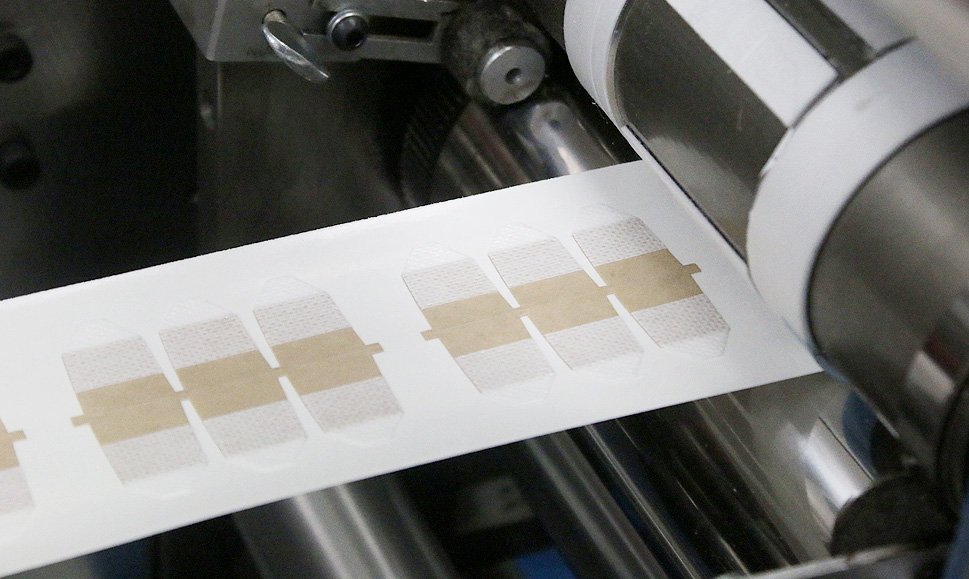

Laminating is the process of joining two or more flexible webs of material together by applying an adhesive and/or pressure and tension to form a duplex or multi-layer stack of materials. Selecting the right substrates, adhesives, and liners are very important in optimizing the lamination stack for processing and product performance. Each material has unique characteristics that contribute in some way to the performance of the final product. Laminating makes it possible to match different adhesives, papers, films, foams, woven, and non-wovens to achieve just the right results. We use industry-leading, servo-driven, converting machines with closed-loop registration to deliver tight tolerance laminations. Products can be rolled or sheeted, depending on final use.

Laminating is the process of joining two or more flexible webs of material together by applying an adhesive and/or pressure and tension to form a duplex or multi-layer stack of materials. Selecting the right substrates, adhesives, and liners are very important in optimizing the lamination stack for processing and product performance. Each material has unique characteristics that contribute in some way to the performance of the final product. Laminating makes it possible to match different adhesives, papers, films, foams, woven, and non-wovens to achieve just the right results. We use industry-leading, servo-driven, converting machines with closed-loop registration to deliver tight tolerance laminations. Products can be rolled or sheeted, depending on final use.

You can trust in AMH’s technical expertise to help you create high-quality, multi-layer laminations that meet your application's requirements.

What Can We Do for Your Business?

Call us 262.255.6150 or send a message to sales.amh@addevmaterials.com TODAY to connect with a specialist about your custom product.

Let's Get Started